When selecting steel wheels for heavy-duty trucks, understanding wheel offset is critical for safety, durability, and performance. Unlike passenger vehicles, commercial trucks require precise offset rims to handle extreme loads and harsh road conditions. This guide clarifies what wheel offset means, why it matters for truck rims, and how to select the best offset wheels for your application—ensuring optimal fitment without compromising stability.

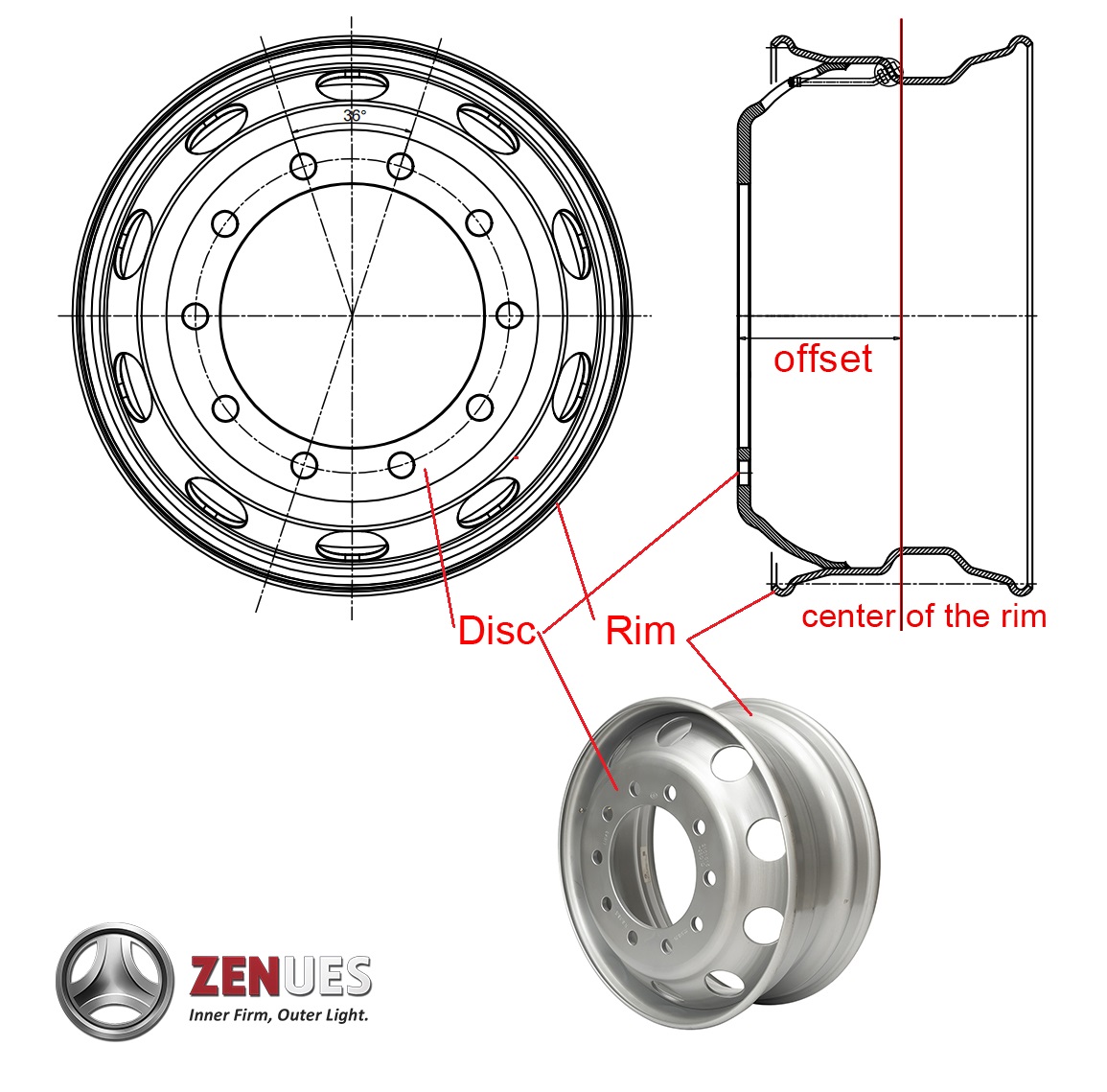

Wheel offset measures the distance between the wheel rim’s mounting hub (where it bolts to the axle, AKA disc) and its centerline. This determines how far the truck rim sits inward or outward from the suspension.

See below picture for wheel offset:

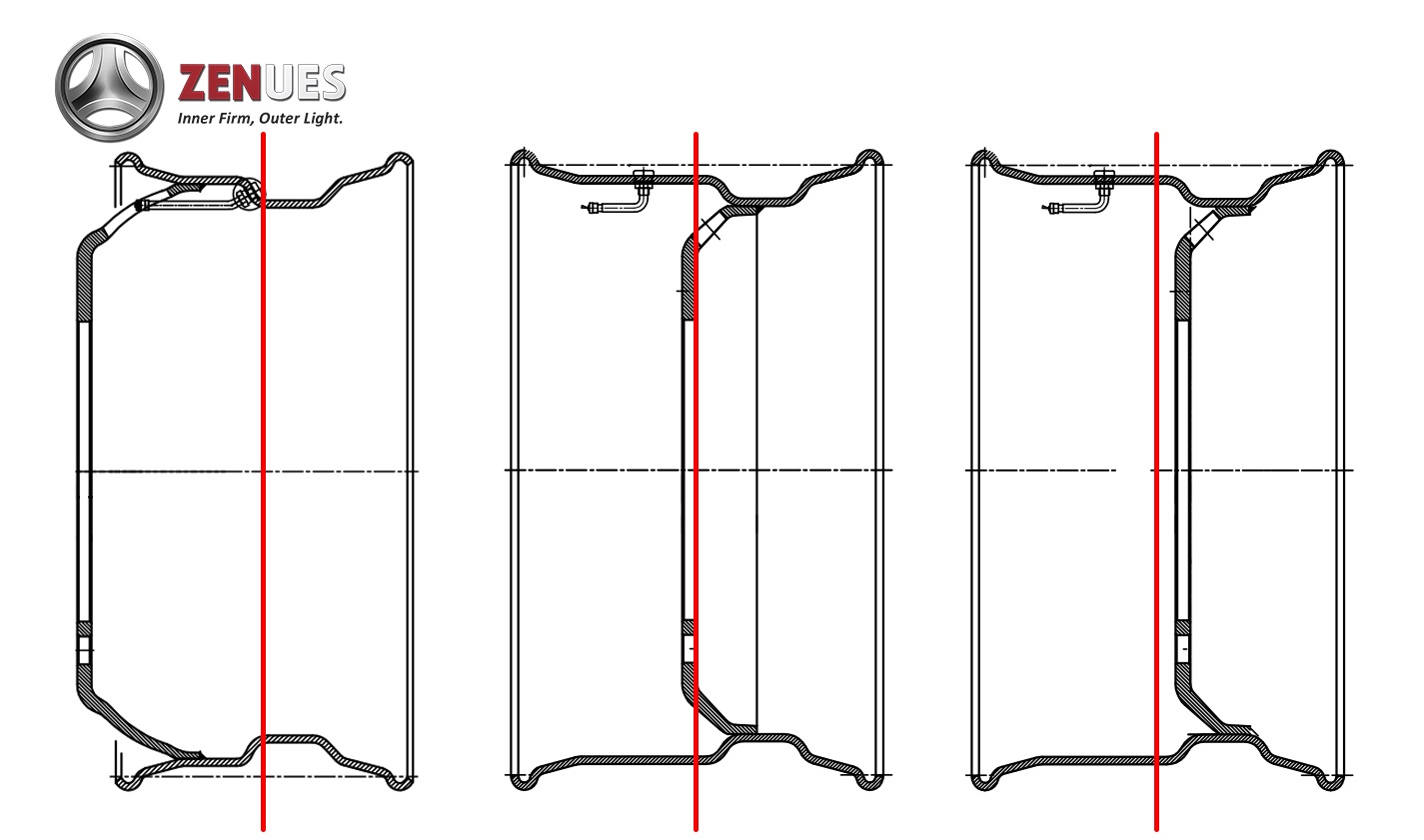

1. Zero Offset (0mm): The hub mounting surface aligns exactly with the wheel’s centerline. Common in some heavy-duty applications.

2. Positive Offset (+mm): The hub sits toward the wheel’s outer edge, tucking the steel wheel closer to the suspension. Most OEM truck rims use positive offset.

3. Negative Offset (-mm): The hub is positioned toward the wheel’s inner edge, pushing the wheel rim outward. Often seen in aftermarket or heavy-haul setups.

Choosing the correct offset wheels prevents rubbing, maintains proper load distribution, and avoids premature wear on suspension components.

Trucks carry significantly heavier loads than passenger vehicles, meaning improper wheel offset can lead to:

1. Excessive strain on wheel bearings and suspension parts

2. Tire contact with brake calipers or suspension arms

3. Reduced stability when hauling heavy loads

1. Wheels protruding beyond fenders, increasing damage risk from debris

2. Added stress on steering linkages, leading to premature failure

3. Potential legal issues due to non-compliant tire protrusion

1. Match OEM Specifications – Check your truck’s manual or existing steel wheels for the factory-recommended offset.

2. Consider Load & Tire Size – Heavier loads may require adjustments, but avoid extreme offset changes (±10mm max from OEM).

3. Verify Backspacing – Measure from the hub mounting surface to the inner rim edge to ensure brake clearance.

4. Test Fit Before Committing – Install one wheel rim to check for interference with suspension or fenders.

1. Avoid excessive negative offset unless specifically needed for deep-dish wheels.

2. Use hub-centric rings if aftermarket offset rims have a larger center bore.

3. Consult a heavy-duty wheel specialist for custom applications.

For high-strength steel wheels designed for commercial trucks, explore our lineup of truck rims with precision-engineered offsets for maximum durability.

Need Expert Guidance? Contact our team for personalized recommendations on offset wheels tailored to your truck’s requirements.

Inquiry Now

If you have any questions, feedback or comments, please fil out the form below and we will reply you back as soon as possible.